Logistic Belts by Nitta

Introduction

Logistics have become an increasing market, thanks to the rapid growth of online shopping.

This requires a highly sophisticated and automated warehouse and distribution system, in which it is inevitable to use many conveyor belts.

This describes various operations of the logistics services, plus a table of possible Nitta belt types per operation. The Nitta product range is much larger than we show here so contact Nitta for your dedicated wishes.

Operations

The total process can be divided in the following operations:

- Horizontal transport

- Inclined/declined transport

- Acceleration

- Accumulation

- Ploughing on/off

- Vertical paddle belts

- Curved conveyors

- 45° infeed strip mergers

- 45° infeed conveyors

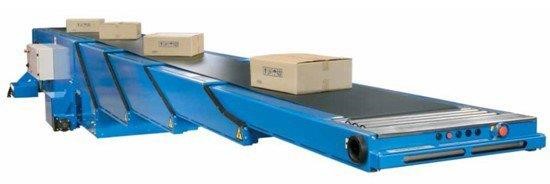

- Telescopic conveyors

- Cross sorter conveying systems

- and also widely seen: Dockshelters

General demands towards conveyor belts

Most systems have sliderbed conveyors, and as there are many people working in these halls, mostly customers require a fabric bottom side with low-noise features. 2-ply belts will do the job, and there is no need to use Polyurethane; PVC is an excellent choice. Colours are mostly black to hide markings of the goods transported over the time. Flame retardant belts are an option for all operations, although unlike airports not every customer requires this feature.

Horizontal transport

Speaks for itself. 2-ply PVC belt with Whisper Antistatic fabric on the bottom, with either a glossy finish or a matt finish. No need to use a 3-ply belt except when lengths are extremely long which we do not expect. Possible belt types:

- 2 LRAF 904 M

- 2 LRWAF 905 M

- 2 LRWAF 905 M FR3

Inclined/declined transport

Mostly sliderbed support, roller support conveyors are more expensive and keeps the parcels less stable. Up to 8° a smooth PVC cover can be used, above that a variety of profiles is suitable. Mostly RT (roughtop), WT (wavetop) or RB (rib); but also our LD (light duty) and GP (gauze). Fabric bottom side can be plain fabric like LR or R, or Whisper Antistatic fabric. Possible belt types:

- 2 LRF 105 LD

- 2 LRF 272 RT 55°

- 2 LRF 2716 WT

- 2 LRF 905 GP

- 2 LRWAF 916 WT FR3 70°

Acceleration

To enter the Cross sorter carousel which travels at fairly high speeds, goods need to accelerate before they reach the 45° infeed conveyors. Belts should be laterally stable, have a softer top cover to ensure a good grip towards the goods, mostly in combination with a low profile like LD, RB or NDP profile. Whisper antistatic fabric on the bottom side is preferable.

Do not combine the accelerating and the 45° infeed in one belt: it would give tracking problems. Possible belt types:

- 2 LRWAF 909 RB

- 2 LRWAF 909 RB FR3

- 2 LRWAF 105 LD

Accumulation and Ploughing on/off

Holding the goods while the belt continues running, or ploughing the goods off the belt sideways. In case the parcels are light and the expected friction between belt and product is low, one can consider a belt with a hard PVC or PU top cover with a matt finish. If the weight and/or friction is higher, a belt with a fabric top or an impregnated top fabric is preferred. Another option is to use nonwoven black felt, either fully nonwoven or with a 2-ply PVC belt as a base for the nonwoven. Possible belt types:

- 2 LRAF 901/901

- 2 LRAF 904 M

- 2 LRAFP 02/BLK2 IM M

- 2 LRWAF 904 M FR3

- 2 LRWAF 907 VB

- 3 LRWAF 901

- 3 LRWAF 901 FR3

- Nifelt 4,0 black

Curved conveyors

Well-designed curved conveyors need belts with non-rigid fabric, and for the logistics industry with 2 plies and a PVC cover with or without a profile. There is no need to use a more expensive PU cover.

For the logistics industry the colour required is mostly black, although other colours are available when required. Possible belt types are:

- 2 NF 906 AS-IM

- 2 NF 906 FR3-IM

- 2 NF 906 SQPR FR3-IM

- 2 NF 906 SQPR-FR3-IM 35°

- 2 NAAF 905 M FR3

- 2 NAAF 906 FR3

- 2 NAAF 906 SB FR3 35°

- 2 NAAF 906 SQPR FR3 35°

- 2 NAAF 906 SQPR-FR3

- 2 NAAF 907 NDP FR3 35°

Pay attention to the special feature of the “ 2 NAAF” series of belts. These are provided with antistatic yarns, but unlike others these antistatic yarns are both in length direction and in cross direction of the belt, to ensure maximum leading away of electrostatic charging; an unique patented feature of Nitta.

45° infeed conveyors

Most automatic distribution systems use a kind of carrousels consisting of a series tilting tables or small conveyors running on a rail system. As these are running at a fairly high speed, the goods which are to be loaded on the carrousel should arrive at the same speed and the only way to achieve this, is to have the infeed conveyor, at the same high speed, under an angle of 45° or 60° towards the carrousel. The head pulley of the infeed conveyor should of course be as close as possible to the edge of the carrousel or the main conveyor. There are two ways to achieve this:

- A series of narrow, parallel conveyors with different, increasing length: strip mergers

- A special conveyor with a head pulley under an angle of 45° or 60°.

45° infeed conveyor with strip mergers

Fairly uncomplicated. Mostly the tail pulley is combined, and the head pulleys differ in distance from the tail pulley so that the gap between merger belt and main line is minimized. Belts should have rigid fabric, covers can either be with a matt finish or with a profile, depending how much grip the customer prefers.

Possible belt types:

- 2 LRWAF 905 M

- 2 LRWAF 905 M FR3

- 2 LRWAF 907 NDP AS

- 2 LRWAF 907 NDP FR AS

- 2 LRWAF 909 RB

- 2 LRWAF 909 RB FR3

45° infeed belt with angled head pulley

The tail pulley, which is also the drive pulley, is 90° to the running direction, as it should be. However the head pulley makes an angle of 45° to the running direction, so that it aligns with the side of the main line.

After passing the head pulley, the belt passes to an extra backflexing pulley which is square to the running direction, and after that back to another angled pulley under the first one, to complete the loop.

Do not use a too soft cover of 35A, this would wear too much due to the twisting of the carried products.

Possible belt types, all with non-monofilament fabrics:

- 2 NF 906 AS-IM

- 2 NF 906 FR3-IM

- 2 NF 906 SQPR FR3-IM

- 2 NAAF 905 M FR3

- 2 NAAF 906 FR3

- 2 NAAF 906 SQPR-FR3

Telescopic conveyors

Used to load or unload trucks in the loading bays. In fact all types of belt with a fabric bottom side can be used. Monofilament fabrics are preferred, and because the speed of (un)loading the trucks is low, there is no need for a Whisper fabric.

In the return part there is a loop to compensate for the difference in conveyor lengths during operation. Suggestion of belt types:

- 2 LRAF 904 M

- 2 LRWAF 905 M

- 2 LRWAF 905 M FR3

Cross sorter conveyor systems

Consists of a large endless rail system on which small chariots are running at sometimes fairly high speeds. The chariots are filled with goods via the 45° merger stations, one product per chariot. The chariots deliver the goods Each chariot is equipped with either a table that can tilt to drop the product carried to a chute at the designated location, or, better of course, with a high-speed conveyor with a belt.

Cross sorter with belts

The dispatch is either done with chutes or with gravity roller conveyors.

Cross sorter with conveyor belts

The conveyor belts in this system must have a lot of grip because of the high-speed start-stop operations and must be laterally stable, most likely with Whisper fabric. Suggestion of belt types:

- 2 LRAF 904 M

- 2 LRF 105 LD

- 2 LRF 905 GP

- 2 LRWAF 909 RB

- 2 LRWAF 907 NDP AS

- 2 LRWAF 907 NDP FR AS

- 2 LRWAF 909 RB

- 2 LRWAF 909 RB FR3

For any further information and available belts for your application, contact your local Nitta distributor or the Nitta office in The Netherlands. See for details our contact page.